|

SAILSetc have prepared a special Italiko for me. I asked if a couple of

things could be provided, and they came up with all the ideas and

implementation. Here are some details.

An

overhead view shows that she has a strong resemblance to an Ikon -- not too

surprising given that she is indeed an Ikon with a "strip" removed

along the centre plane. The servo tray is now located on one side, and the

radio pot on the other. You can have the radio pot recessed under a deck

patch if you really want this, but I've opted to have the screw-top lid to the

pot accessible directly. Much better if there is any chance you'll need to

get to the Rx to change frequency, or to get to the battery for a longer

event. It now makes it a much more realistic option to run with a small,

light, low capacity Rx battery pack. Such a pack can be replaced every

fourth race, say, and allows you to put the 100 gm you've saved into corrector

weight right on the bottom of the hull where it will do most good. An

overhead view shows that she has a strong resemblance to an Ikon -- not too

surprising given that she is indeed an Ikon with a "strip" removed

along the centre plane. The servo tray is now located on one side, and the

radio pot on the other. You can have the radio pot recessed under a deck

patch if you really want this, but I've opted to have the screw-top lid to the

pot accessible directly. Much better if there is any chance you'll need to

get to the Rx to change frequency, or to get to the battery for a longer

event. It now makes it a much more realistic option to run with a small,

light, low capacity Rx battery pack. Such a pack can be replaced every

fourth race, say, and allows you to put the 100 gm you've saved into corrector

weight right on the bottom of the hull where it will do most good.

A

side view shows the shape of the rocker. If you are a designer, this'll

tell you more than it tells me right now, but I see quite a long entry, quite a

shallow entry angle, with maximum rocker aft of mid-hull. Like the current

crop of the SAILSetc designs, she has a peaked foredeck, giving a powerful, high

mast ram, and high mast partners which clamp the mast as a cantilever and

thereby increase its effective stiffness four-fold. Really. A

side view shows the shape of the rocker. If you are a designer, this'll

tell you more than it tells me right now, but I see quite a long entry, quite a

shallow entry angle, with maximum rocker aft of mid-hull. Like the current

crop of the SAILSetc designs, she has a peaked foredeck, giving a powerful, high

mast ram, and high mast partners which clamp the mast as a cantilever and

thereby increase its effective stiffness four-fold. Really.

In

order to get the position and inclination of the bulb millimetre-perfect, a pair

of small M2 machine screws are tapped into the base of the bulb's slot.

Screw 'em in, or screw 'em out, to raise and lower the bulb nose or tail.

Very effective. In

order to get the position and inclination of the bulb millimetre-perfect, a pair

of small M2 machine screws are tapped into the base of the bulb's slot.

Screw 'em in, or screw 'em out, to raise and lower the bulb nose or tail.

Very effective.

Update: Did I say the machine screws in the bulb slot were

good? I now tune my bulb cant for every event, easily and quickly, by

dialling in exactly the amount of nose-up I want with a quarter- or half-turn of

a screw. Very slick.

This

is a view looking forward. In the distance are two switches set into the

bulkhead, under the foredeck flange, one for On/Off, and one to program the RMG

winch 'cos my radio system is "intelligent". Also under the

flange is a turning block for the sheeting line to the mainsail. In the

foreground is the main sheet post, which I have as low as possible, rather than

higher up, tucked under the boom. The current arrangement has the post

adjustable as a friction fit, and works very well if it tucks under the boom,

but otherwise the post needs to be screwed in place if it is to take the

sheeting loads associated with "vang sheeting". Then, if you do

screw it in place, you need to have greased it well beforehand, and to

periodically remove it from the hull, otherwise it seizes in place, particularly

if you sail in salt water. You'll also note that the lip to the servo tray

has been cut back a little to allow the sheeting line to run from the winch to

the rear thru-deck fitting. This cut-back is needed if you are running a

step-down or snail drum, and not if you run a "normal" single or

double drum. This

is a view looking forward. In the distance are two switches set into the

bulkhead, under the foredeck flange, one for On/Off, and one to program the RMG

winch 'cos my radio system is "intelligent". Also under the

flange is a turning block for the sheeting line to the mainsail. In the

foreground is the main sheet post, which I have as low as possible, rather than

higher up, tucked under the boom. The current arrangement has the post

adjustable as a friction fit, and works very well if it tucks under the boom,

but otherwise the post needs to be screwed in place if it is to take the

sheeting loads associated with "vang sheeting". Then, if you do

screw it in place, you need to have greased it well beforehand, and to

periodically remove it from the hull, otherwise it seizes in place, particularly

if you sail in salt water. You'll also note that the lip to the servo tray

has been cut back a little to allow the sheeting line to run from the winch to

the rear thru-deck fitting. This cut-back is needed if you are running a

step-down or snail drum, and not if you run a "normal" single or

double drum.

A

close view of the transom shows a number of features. On the right is the

thru-deck fitting that takes the line from the winch and feeds it to a turning

block. This block is a "Hales" with measurably lower friction

than, erm, some others I'm not going to mention. In the centre of the aft

deck is the new rudder post upper bearing, secured by a screw. The round

white patch on the transom covers an access hole for the tiller arm, making it

very much easier to remove the rudder than before. And yes, she's called

"Milly 3" in honour of my main supporter and long-time, ah, sponsor. A

close view of the transom shows a number of features. On the right is the

thru-deck fitting that takes the line from the winch and feeds it to a turning

block. This block is a "Hales" with measurably lower friction

than, erm, some others I'm not going to mention. In the centre of the aft

deck is the new rudder post upper bearing, secured by a screw. The round

white patch on the transom covers an access hole for the tiller arm, making it

very much easier to remove the rudder than before. And yes, she's called

"Milly 3" in honour of my main supporter and long-time, ah, sponsor.

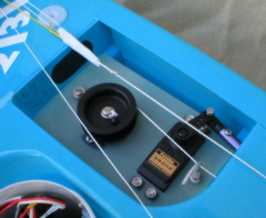

A

close-up of the servo tray shows that the winch and rudder servo are mounted on

a simple tray, that is screwed down in the opening. I've put a simple

hooked piece of 3 mm aluminium rod next to the rudder servo to guide the

sheeting line away from the rudder horn as it approaches the winch. This

is needed 'cos the RMG step-down drum has a counter-clockwise spiral, and feeds

on the right. A clockwise spiral would feed on the left, and the line

wouldn't have to be kept away from the rudder horn in this case. A

close-up of the servo tray shows that the winch and rudder servo are mounted on

a simple tray, that is screwed down in the opening. I've put a simple

hooked piece of 3 mm aluminium rod next to the rudder servo to guide the

sheeting line away from the rudder horn as it approaches the winch. This

is needed 'cos the RMG step-down drum has a counter-clockwise spiral, and feeds

on the right. A clockwise spiral would feed on the left, and the line

wouldn't have to be kept away from the rudder horn in this case.

The pot holding the Rx and battery is specially shaped. A lower segment

has been cut off it (not visible in the photos) and a flat plate fitted instead

so it can recess in the hull without fouling the side of the boat.

Here

is the first "special" feature -- a length of deck track that has been

recessed for the shroud attachment to the gunwale. The idea is that it

allows a far wider range of shroud attachment points than normal. The

track is in fact pierced with holes at regular intervals, and the set-screw on

the slide is longer than normal, so it sets into a hole. Here

is the first "special" feature -- a length of deck track that has been

recessed for the shroud attachment to the gunwale. The idea is that it

allows a far wider range of shroud attachment points than normal. The

track is in fact pierced with holes at regular intervals, and the set-screw on

the slide is longer than normal, so it sets into a hole.

Update: I've now had a chance to see how this works, and it

works well. One change I have had to make, however, is to space the holes

more closely together. It turns out that the mast bend is very

sensitive to shroud attachment position on the hull. Just a small shift in

shroud position can bring a bunch of wrinkles into the mainsail luff.

Internally, the hull has been particularly strengthened at the chain-plate

area to take higher than "normal" shroud tensions, and shroud tensions

which act further aft than "normal" as well.

A similar idea has been applied at the foredeck, where a long length of deck

track has been recessed to provide both pivot points, and sheet reeving

points. The regular holes in the track are clearly visible, and they allow

complete freedom to choose the pivot point and the sheeting radius in any

rig. The mast ram is set into the end of the track.

The

track slides are set in position using a spring-loaded "pin" instead

of set screws, as illustrated. The "spring" and "pin"

are simply a length of stainless steel wire in an "L" shape, with the

long end of the spring set into a second track slide, seen on the right of the

picture. The pin end secures the eyebolt slide, on the left of the

picture, by passing through the hole that normally takes the set-screw, and

locating in one of the track holes below. Very effective, quick and easy

to change and adjust. The

track slides are set in position using a spring-loaded "pin" instead

of set screws, as illustrated. The "spring" and "pin"

are simply a length of stainless steel wire in an "L" shape, with the

long end of the spring set into a second track slide, seen on the right of the

picture. The pin end secures the eyebolt slide, on the left of the

picture, by passing through the hole that normally takes the set-screw, and

locating in one of the track holes below. Very effective, quick and easy

to change and adjust.

The whole point of these recessed tracks, of course, is to be able to vary

jibstay and topping lift tension by varying pivot offset and shroud offset, as

per the pages on rig tensions, and as

permitted by the special rigging fittings, below.

Update: The adjustable pivot point and sheeting point are

excellent. Almost too good in a way, because I've got myself into a muddle

more than once by making too many changes and losing what little tune I

had. You do need a clear head as you shift the pivot and sheet reeving

points to be sure you are doing the right thing. Leave 'em alone if you're

just messing about!

The

second "special" feature is the use of prototype SAILSetc boom

fittings. The special fitting is a laser-cut stainless steel item that

effectively provides an eye for the boom, much like a boom band for an arrow

shaft boom. They slide up and down and can be locked in any

position. The fitting has a very small peg that locates in the hole found

in the standard boom slide. The fitting replaces the little shackle that

some skippers use at the aft end of the boom for the sheet attachment, and

provides the pivot arrangement at the forward end. These two pictures show

the fitting being used to locate the pivot on my No.1 rig, which is a length of

line that hooks into one of a row of holes under the boom. The length of

line, the hook, and its attachment to the deck are shown in the earlier picture

of the foredeck and the deck track. The

second "special" feature is the use of prototype SAILSetc boom

fittings. The special fitting is a laser-cut stainless steel item that

effectively provides an eye for the boom, much like a boom band for an arrow

shaft boom. They slide up and down and can be locked in any

position. The fitting has a very small peg that locates in the hole found

in the standard boom slide. The fitting replaces the little shackle that

some skippers use at the aft end of the boom for the sheet attachment, and

provides the pivot arrangement at the forward end. These two pictures show

the fitting being used to locate the pivot on my No.1 rig, which is a length of

line that hooks into one of a row of holes under the boom. The length of

line, the hook, and its attachment to the deck are shown in the earlier picture

of the foredeck and the deck track.

The

idea is extended to provide for a ball-raced pivot fitting. Two of the

stainless steel fittings are joined together around a ball race. A wire

hook locates in the ball race and attaches to deck, and the whole assembly can

then slide along the boom. In fact a couple of prototypes were needed to

get this just right, since the fitting is not symmetrical -- the aft side of the

housing needs to be longer than the forward side, so the ball race is held at

the correct angle to the boom. This fitting is shown on my No.2 rig, where

there is less of a need to adjust the length of the pivot. The

idea is extended to provide for a ball-raced pivot fitting. Two of the

stainless steel fittings are joined together around a ball race. A wire

hook locates in the ball race and attaches to deck, and the whole assembly can

then slide along the boom. In fact a couple of prototypes were needed to

get this just right, since the fitting is not symmetrical -- the aft side of the

housing needs to be longer than the forward side, so the ball race is held at

the correct angle to the boom. This fitting is shown on my No.2 rig, where

there is less of a need to adjust the length of the pivot.

If any of these new fittings interest you, please contact SAILSetc

for details on availability and pricing. Tell 'em Lester sent you...

Update: I've had a chance to sail the Italiko in a number of

events, and I can report excellent news. I find her just as fast as the

Ikon in all points of sailing, and almost certainly faster on the run. She

changes her balance (helm) much less violently than the Ikon, and I've not yet

experienced "snap" weather helm. She'll still develop lee helm

in the lulls and weather helm in the puffs, but it is all much more

controllable. So when the breeze is at the top of "A" rig, I

find I can keep up with other Ikons just because she is easier to sail, and the

slightly narrower beam (and hence slightly lower stability) doesn't really seem

to matter that much. Now if only I can learn to race better...

2005-12-18 |