|

3D Printed Sail Box Fittings

by Lester Gilbert

A new sail box for the 2018 10R World Championships in

Germany seemed a good simple starter project for my new-to-me 3D printer.

I’d kept my 10R rigs in individual plastic sail bags previously, which

did not make for quick rig changes if needed.

3D printing

To test the home 3D printing waters I had purchased a

second-hand Lulzbot ‘Mini’ using 2.85 mm filament.

The Mini has a modest build volume of around 6” x 6” x 6”, fine for the

small things I wanted to make, and some useful features which I have come to

greatly appreciate – automatic bed levelling;

automatic nozzle cleaning; a

heated bed with a PEI coating; an

all-metal hotend; interchangeable tool

heads; highly configurable driver and

slicer software (Lulzbot ‘Cura’) pre-loaded with printing profiles for a range

of filaments; an open architecture;

and readily available manuals, guides,

help, and parts from the Lulzbot Web site.

I had previously worked with a Flashforge Dreamer at the University of

Southampton with rather mixed results, and was initially nervous of any

substantial investment.

[Ed. Lulzbot ceased trading for a while, but on their return they targeted

the commercial, rather than the consumer, market, with prices to match.

When I was ready to move to a larger build table I invested in a Prusa Mk3

instead, it has been quite excellent.]

My continued association with the University as an ‘Emeritus

Fellow’ allowed me to use its licence for an industrial strength 3D CAD

application, Dassault ‘Solidworks’.

The learning curve for any 3D CAD is quite steep, and I found it more or less

vertical for this software which is otherwise used to design jet aircraft.

Fortunately, I could access some good tutorial and training materials to

help me along. For anyone new to 3D

printing, securing good consumer-grade (rather than DIY hobbyist) hardware is

reasonably straightforward, but finding and learning 3D CAD design software is

likely to be somewhat more challenging.

Designs

My previous sail boxes used clips to hold the masts, and I

found that, over time, they marked the soft aluminium or scratched the carbon

fibre. I then tried plastic-coated

clips, but found they were not suited for outdoor use, the plastic degraded and

then disintegrated and the clips rusted.

For this sail box, I went with a cup to hold the mast head and backstay

crane, and a loop and step to hold the mast heel, as illustrated in

Figure 1

and Figure 2.

There were two design details of significance.

One was to match the depth of the cup to the drop between the loop and

the step of the heel fitting, so that there was enough room to place the rig in

the cup before dropping the heel through the loop onto the step.

Yup, there went a couple of early prototype prints into the bin before I

fully understood that inter-relationship.

Two was to make the cup a little wider than simply the diameter of the

mast plus a little allowance. This

was because the mast is inserted at an angle, and some distance, into the cup

before it can be positioned above and dropped into the retaining loop at the

heel. Yup, there went another

prototype print.

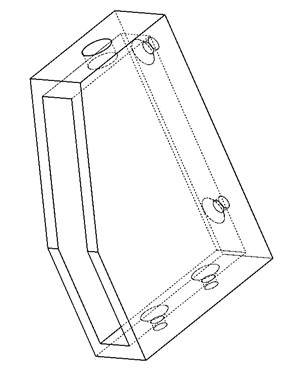

Figure

1.

Masthead cup fitting in initial wireframe display.

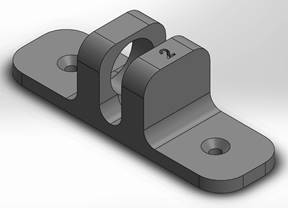

Figure

2.

Mast heel fitting in final isometric surface rendering.

For a little bling, I decided to decorate the box with corner

scuff plates and to provide some reinforcement, one such plate illustrated in

Figure 3.

Using 3D CAD and 3D printing meant I could easily fabricate a corner

plate that was, for example, 104 degrees to suit the angle of the box’s leech

run, or 85 degrees to suit the box’s angled base for upright stability when

opened.

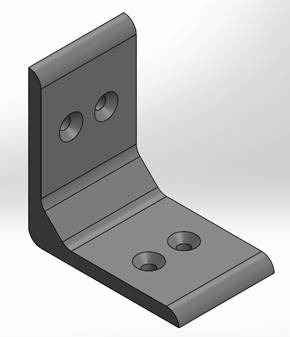

Figure 3.

Corner reinforcement.

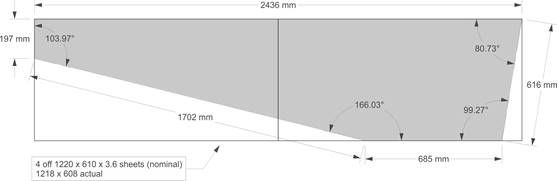

I sketched out the sail box in Corel Draw, a 2D vector

drawing application. The layout of

the box panels is illustrated in Figure

4.

Figure

4.

Box panels laid out in Corel Draw.

The box build didn’t go well.

I cut out the 3.2 mm plywood panels separately and then found slight

dimensional differences between the left hand and right hand panels (should have

cut the left and right panels as one).

I cut the left and right panels using the pattern on the same hand and

found that, when mirrored, they then sagged in the same direction, with the left

panel sagging convex and the right panel sagging concave (should have mirrored

the wood before cutting). I decided

to go for a ‘neat’ build, rebating and mitering the lid battens.

Now while the plan might have called for a 52 degree mitre to give the

104 degree angle between two battens, for example, I simply didn’t have the

woodworking skills (or the sufficiently accurate fence) to cut a 52 degree mitre.

I think it turned out to be around 55

degrees and not square to the batten which was enough to make the join a little

wobbly rather than firm. I failed

to learn from my mistake with the panels, and again cut the rebates using the

template on the same hand. When

mirrored to give me left and right, well, all the rebates on one half were on

the wrong side. I decided the sail

box needed to tip forward by 10 degrees to have upright stability when opened,

so I angled the base of each lid by 10 degrees.

Wrong, the total tip needed to be divided between the lids, and each base

should have been angled by something like 5 degrees (well, 7 degrees, being 10*cos(45),

if the lids were to be opened to 90 degrees).

But I now know how to make wizard sail boxes.

Prints

None of the printed fittings were intended for longevity,

instead being vehicles for learning my way around the Lulzbot Mini printer, the

Cura driver and slicing software, and the Solidworks 3D CAD application.

I decided to print using PLA filament, which has the two advantages of

being an easily printed material, and of being biodegradable following the

inevitable errors and breakages.

The results are illustrated in place in the following photos.

Figure

5.

Masthead cup fitted in the box.

The cup took a few prototype prints before I was satisfied.

The nature of 3D filament printing is that material overhang

(ie material which is unsupported during

printing) should be avoided, meaning the cup could not be printed on its side or

end but only with its opening uppermost.

This meant that the interior of the cup cooled rather more quickly than

the cup walls, such that the base lifted away from the print plate at the

corners. The first few prints were

abandoned as the cup slowly turned into a hollow squared-off banana.

Interestingly, the fix was to increase tool head cooling to the model to

reduce the subsequent temperature differential between wall and base.

Figure

6.

Mast heel fitted in the box.

Figure

7.

Corner reinforcements in the box.

If I were to revisit the project, while I might prototype in

PLA again, I would make final prints in a less brittle material, perhaps

co-polyester (nGen, nVent), nylon, bridge nylon, ABS, ASA, or similar.

When screwing a fitting to the box, I found that there was a *very*

narrow range of torque between fixed to the wood but wiggle-able, so not quite

fixed enough, and fixed to the wood but now cracked along one of the filament

layers (yup, it was ‘fixed’, there went some more prints into the bin).

That range would have been a little wider with one of the alternative

filament materials mentioned. I

knew already that you couldn’t screw any of these thermoplastics tightly (as in

using a wood screw through an unreinforced hole), but hadn’t appreciated just

how brittle they were. They were

more than adequately strong, but rather prone to local compression failure.

|

.htm_cmp_lghome010_bnr.gif)